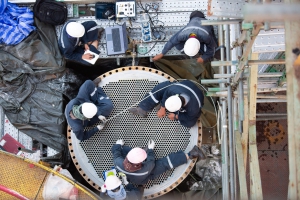

EDDY CURRENT TESTING

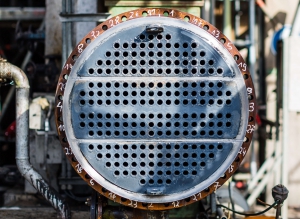

Eddy current testing is a noncontact method used to inspect nonferromagnetic tubing. This technique is suitable for detecting and sizing metal discontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks in nonferrous materials.

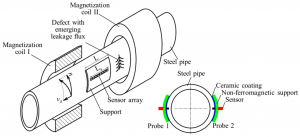

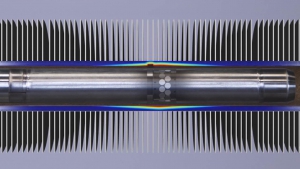

MAGNETIC FLUX LEAKAGE

Magnetic flux leakage (MFL) is a fast inspection technique, suitable for measuring wall loss and detecting sharp defects such as pitting, grooving, and circumferential cracks. MFL is effective for aluminum-finned carbon steel tubes because the magnetic field is almost completely unaffected by the pressence of such fins.

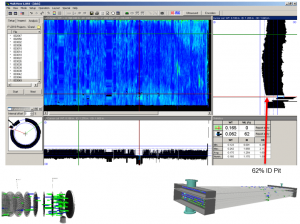

INTERNAL ROTARY INSPECTION SYSTEM

The ultrasonic IRIS option is used to inspect a wide range of materials including ferrous, nonferrous, and nonmetallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts.

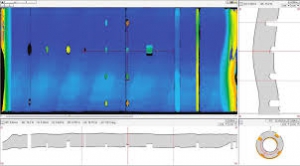

NEAR FIELD TESTING

The near field testing (NFT) technology is a rapid and inexpensive solution intended specifically for fin-fan carbonsteel tubing inspection. NFT is specifically suited for the detection of internal corrosion, erosion, or pitting on the inside of carbon steel tubing.

The NFT probes measure lift-off or “fill factor” and convert it to amplitude-based signals (no phase analysis). Because the eddy current penetration is limited to the inner surface of the tube.

REMOTE FIELD TESTING

Remote field testing (RFT) is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferritic stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts. Olympus remote field probes and the MultiScan™ MS 5800 are used to successfully inspect heat exchangers, feedwater heaters, and boiler tubes, around the world.