MAGNETIC FLUX LEAKAGE

Magnetic flux leakage (MFL) is a fast inspection technique, suitable for measuring wall loss and detecting sharp defects such as pitting, grooving, and circumferential cracks. MFL is effective for aluminum-finned carbon steel tubes because the magnetic field is almost completely unaffected by the pressence of such fins.

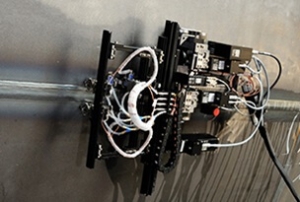

CRAWLER UT GAUGING

Battery operated, encoded crawler with 5 MHz, dry coupled wheel probe. Supplied with a 50 metre umbilical cable for access to the top of the highest storage tanks methods. The Scorpion is a rugged remote access ultrasonic (UT) crawler designed for cost effective ultrasonic inspection on ferro-magnetic structures such as storage tanks, vessels and offshore installations without the need for costly scaffolding or rope access associated with UT thickness gauging.

High resolution B-scan image

Simple profile, or full amplitude display

Permanently stored data for recall to assist with RLA & RBI trend forecasting

No couplant or paint removal required

APPLICATIONS

Tank Thickness Gauging without Rope Access / Scaffolding

Pressure vessels and offshore installations Thickness Gauging

PERSONNEL QUALIFICATIONS

ISO 9712 ( PCN, RTC, CSWIP), ASNT Level 2/3

ACOUSTIC EMISSION

Acoustic Emission Testing (AET) is a Non-Destructive Testing (NDT) method that is used to analyse emitted sound waves caused by defects or discontinuities. These acoustic waves are induced by small deformations, corrosion or cracking, which occur prior to structure failure. It is therefore possible, with AET, to locate structural defects and to monitor the propagation and development of discontinuities.

APPLICATIONS

Storage tank Bottom floor inspection / Full Integrity Testing

No need to evacuate the load from the storage tank

Pressure vessels, Gas Bottles Integrity Testing without evacuating load

TRACK RECORD:

Storage Tank Floor Bottom Inspection

FRP vessels

PERSONNEL QUALIFICATIONS

ISO 9712 ( PCN, RTC, CSWIP), ASNT Level 2/3

AMERICAN PETROLEUM INSTITUTE (API) SERVICES

The American Petroleum Institute (API) is a well recognized organization for laying the codes in the refinery & processing industry. We can perform jobs as per the API codes in:

Pressure vessel inspection

Pipeline inspection

Above ground storage tank inspection

Risk based inspection

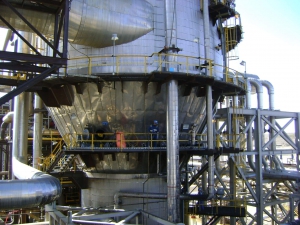

Refractory inspection

Fitness for service

Damage mechanism identification

Risk based inspection & fitness for service pays of very well from a safety & financial point of view

We have well trained engineers who are qualified, experienced and certified by the American Petroleum Institute in different disciplines including:

API 510

API 570

API 653

API579

API 571

API 580

API 936 to tackle any challenging jobs as per API codes .