Windmill Inspection & Maintenance

Inspecting the condition of wind turbines is vital at various stages of the project lifecycle. It allows all interested parties to reassure themselves of the quality of the turbine’s fabrication, maintenance and performance. In some countries, regular inspections are a legal requirement; and many insurance companies insist on them when issuing a policy.

DNV GL offers a complete range of inspection services for onshore and offshore wind turbines and their components.

Our inspections provide completely objective and independent information on:

- The condition of wind turbines and assets

- The performance of maintenance and repairs

This helps you reduce risks, reassure stakeholders and meet regulations.

Inspection at any stage

Inspections can be carried out at any point during the fabrication, commissioning and operation of the equipment. Typical milestones requiring inspections include:

- Manufacturing of components

- Storage and / or transport of equipment

- Assembly of assets

- Commissioning the project

- Monitoring project milestones that trigger financial rewards to stakeholders

- Assessing asset performance and condition during operation

- Planning and evaluating maintenance

- Investigating damage

- End of warranty

- Extending the lifetime of a wind farm

Inspections can cover all components of wind power generation systems including the rotor, nacelle, tower, foundation and electrical system. We can inspect both onshore and offshore facilities – including offshore substation platforms.

Reliable objectivity

All our inspections are carried out by highly qualified inspection engineers with many years of experience in the wind energy sector. They are fully trained on all relevant safety, measurement and operational topics, allowing them to work in a wide range of locations and weather conditions, and with different equipment designs. Each of our experts has obtained a Level 3 Supervisor in Rope Access Technique qualification.

We carry out inspections around the world. Renowned for our independence and objectivity, we share inspection results with owners, investors and manufacturers, so all interested parties can have full confidence in the project.

We are able to provide CAP, CAS, Special Survey, Intermediate Survey / Annual Survey & Close up Surveys.

Wind Turbine Tower Repair Services

MEGATECH’ tower services ensure that wind turbine towers have solid structural integrity while also maintaining a clean and attractive appearance, including:

- Cleaning

- Coating/Painting

- Weld Inspection

- Mast Inspection

- Caulking

- Dent Removal

Wind Turbine Nacelle Repair Services

Wind turbine nacelles serve the important role of housing the generating components of wind turbines. MEGATECH’ nacelle services ensure that critical turbine componentry remains efficiently covered and protected, along with improving the physical appearance of the nacelle. Services include:

- Cleaning

- Composite Repairs

- Weather Station Replacement/Repair

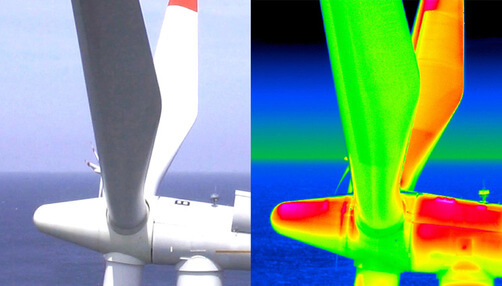

Wind Turbine Blade Repair Services

Wind turbine blades are routinely subjected to extreme operating conditions. Manufacturing defects and the stress they are routinely subjected to during normal operations can combine to accelerate blade degradation. Other damages we inspect for and repair include:

- Leading-Edge Erosion

- Bond-Line Failures

- Moisture Intrusion

- Freeze/Thaw Cycling

- Transportation

- Lightning Damage